How to Choose the Right CNC Machine for Your Business

- Calvin Wu

- Apr 29, 2023

- 4 min read

Introduction

Choosing the right CNC machine for your business is crucial for optimizing productivity, efficiency, and profitability. This guide will help you navigate the process of selecting the perfect CNC machine for your specific needs by considering factors like machine size, capabilities, cost, and brands.

Assessing Your Business Needs

Before selecting a CNC machine, assess your business needs by considering the following factors:

Materials: Determine the types of materials you will be working with, such as metals, plastics, or composites.

Machining operations: Identify the machining processes you will be performing, such as milling, turning, drilling, or cutting.

Production volume: Evaluate your expected production volume and the level of automation required to meet your needs.

Budget: Establish a budget for the initial investment, ongoing maintenance, and software costs.

Types of CNC Machines

There are various types of CNC machines to choose from, including:

1. CNC mills: Used for cutting, drilling, and shaping materials, CNC mills are versatile and suitable for a wide range of applications.

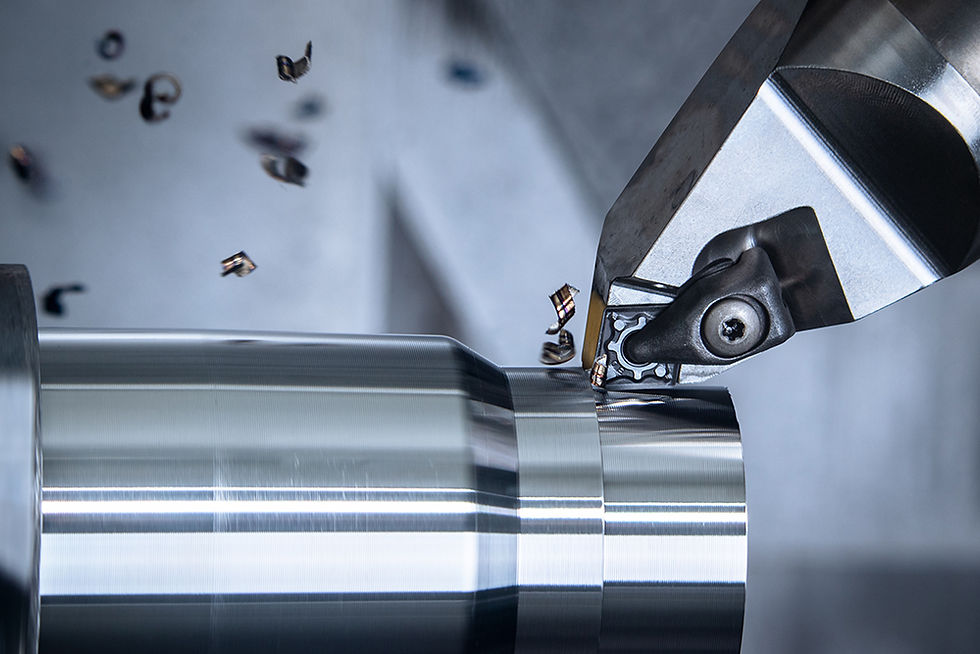

2. CNC lathes: Ideal for turning and shaping cylindrical parts, CNC lathes offer high precision and are commonly used in industries like aerospace and automotive.

3. CNC routers: Primarily used for cutting and shaping wood, plastics, and soft metals, CNC routers are popular among sign makers and furniture manufacturers.

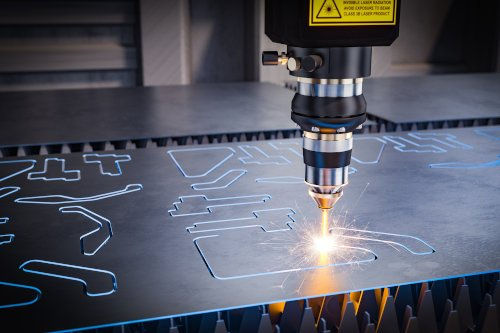

4. CNC laser cutters: These machines use a focused laser beam to cut or engrave materials with high precision and speed, making them suitable for detailed work and intricate designs.

5. CNC plasma cutters: Using a high-velocity jet of ionized gas, CNC plasma cutters can quickly and efficiently cut through metal sheets.

6. CNC 3D printers: Employing additive manufacturing technology, CNC 3D printers build objects layer by layer from various materials, including plastics, metals, and composites.

Popular CNC Machine Brands

Some of the most popular CNC machine brands include:

Founded in 1983, Haas Automation is one of the largest manufacturers of CNC machine tools in the world. The company's products include vertical and horizontal machining centers, lathes, rotary tables, and indexers. Haas is known for its high-quality, reliable machines and excellent customer service.

Yamazaki Mazak Corporation is a Japanese manufacturer of CNC machine tools, including turning centers, milling machines, and laser-cutting machines. The company has a reputation for innovation and has been at the forefront of many technological advances in the industry.

DMG Mori is a German-Japanese company that specializes in the production of CNC machines, including milling machines, lathes, and turning centers. The company is known for its high-quality, precise machines, and its focus on digitalization and automation.

Okuma Corporation is a Japanese company that produces CNC machines for a variety of industries, including aerospace, automotive, and medical. The company is known for its advanced technologies, including its THINC control system, which provides users with advanced features and capabilities.

Hurco Companies, Inc. is a U.S.-based manufacturer of CNC machines, including vertical machining centers, horizontal machining centers, and turning centers. The company is known for its innovative technology, such as its patented UltiMotion motion control system, which reduces cycle time and improves surface finish.

Fadal Engineering is a U.S.-based manufacturer of CNC machines, including vertical machining centers and turning centers. The company is known for its affordable, high-quality machines and its focus on customer satisfaction.

Doosan Machine Tools is a South Korean manufacturer of CNC machines, including turning centers, milling machines, and machining centers. The company is known for its high-quality, reliable machines and its commitment to sustainable manufacturing practices.

Makino Milling Machine Co., Ltd. is a Japanese company that produces CNC machines for a variety of industries, including aerospace, automotive, and medical. The company is known for its advanced technologies, including its Super Geometric Intelligence control system, which provides users with advanced features and capabilities.

Fanuc Corporation is a Japanese company that produces a range of CNC machines, including turning centers, milling machines, and machining centers. The company is known for its advanced robotics and automation technologies, which have revolutionized manufacturing processes worldwide.

Selecting the Right CNC Machine

When choosing the perfect CNC machine for your business, consider the following factors:

Size and footprint: Ensure the machine will fit within your available workspace and can be easily accessed for maintenance and operation.

Capabilities: Choose a machine that can perform the necessary machining operations, is compatible with your materials, and meets your production volume requirements.

Precision and accuracy: Look for a machine that offers the required level of precision and accuracy for your specific applications.

Speed and productivity: Evaluate the machine's speed and productivity to ensure it can meet your production goals.

Maintenance and support: Investigate the ease of maintenance, availability of replacement parts, and the manufacturer's customer support to minimize downtime and ensure smooth operation.

Software and Control Systems

The software and control systems used with your CNC machine can greatly impact its performance and ease of use. Consider the following factors when selecting a machine:

Compatibility: Make sure the CNC machine is compatible with your existing software or the software you plan to use.

User-friendliness: Choose a machine with an intuitive control system that makes it easy for operators to learn and use.

Flexibility: Opt for a control system that offers customization options and can accommodate future upgrades or expansions.

Conclusion

Selecting the right CNC machine for your business involves careful consideration of your specific needs, budget, and the various factors discussed in this guide. By evaluating the types of CNC machines, popular brands, and key features, you can make an informed decision and invest in a machine that will help your business grow and prosper.

Comments